The First Domestic Full-Automatic Intelligent Welding Production Line for Pouch Cell VDA Modules was successfully off line

In late June 2020, YIFI Laser's pouch cell battery flexible intelligent module assembly line successfully was off line and has already passed the acceptance of the customer, a head enterprise in industry. This production line is the first domestic intelligent assembly line for soft-pack battery modules. It uses the independent intellectual property rights of the module automatic Busbar board mounting technology and real-time welding quality monitoring technology. The efficiency is up to 15PPM. It is compatible with multi-standard batteries for mixed-line production according to customer needs.

Due to its core advantages such as high energy density, outstanding safety performance, flexible layout design, and long battery life, soft-pack batteries have rapidly become the “sweet pastry” of passenger electric vehicles since 2018. In 2020, power battery manufacturers such as Guoxuan High-tech, Yiwei Lithium Energy, Funeng Technology, Hengda Canai, and Gateway Power have plans to expand production capacity of soft packs. The rapid advancement of the soft-pack battery market has brought our company a broader development space. However, due to the low shell hardness and complex module technology, the group technology has always been the weakness of the soft pack battery to achieve efficiency improvement and cost reduction.

Break through the weakness of soft-pack batteries and accelerate the application of soft-pack batteries in passenger electric vehicles

Improving efficiency and reducing costs of soft-pack batteries is mainly reflected in the complex process of soft-pack battery modules and higher requirements for battery packs, so the degree of automation is low and more labor costs are required. The consistency is poor, the manufacturing cost is high, the variety is single, and the adaptability is low.

Aiming at solving the pain points of the soft pack battery pack, YIFI laser’s soft pack module intelligent assembly line has three core advantages:

First, only one fixed employee is required for the whole line, with high automation and high production efficiency.

The flexible intelligent soft-pack battery module assembly line of YIFI Laser has 28 processes with modular decomposition and integration design. Based on the research and development concept of "flexible intelligent manufacturing", YIFI Laser has conducted continuous equipment and process innovation, fully adopting Fully Automatic Folding and Gluing Technology, Automatic Tab Cutting and Inspection Technology, Automatic Cell Stacking Technology, Automatic Top and Bottom Plate Laser Welding Technology, Automatic Module Busbar Mounting Technology and Real-Time Welding Quality Inspection and other core technologies.

Therefore, YIFI Laser’s flexible intelligent soft-pack battery module assembly line realizes the full automation of all parts and components feeding, sorting, assembly, and inspection, and can seamlessly connect with the intelligent logistics distribution system. Only one person is required for a fixed station throughout the process. This line is a truly fully automated, informatized and intelligent soft pack battery module assembly line.

Second, it is suitable for most mainstream soft-pack batteries and modules, and can be compatible with modules of multiple specifications for mixed-line production at the same time.

In view of the variety of specifications of soft pack batteries, low product hardness and changeability, and the objective current situation of combining multiple specification modules in the same PACK battery pack, YIFI Laser has creatively realized the fusion application of flexible tooling and fixture design and intelligent MES management system based on a five-axis flexible welding station. This line improves the adaptive range of equipment through the flexible tooling and fixture and achieves the management of different module parameters through the MES system, realizing one-click to adjust or set the model parameters and mixed-line production of modules of different sizes.

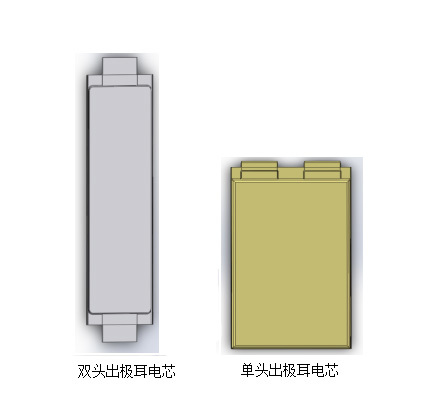

Therefore, The flexible intelligent soft-pack battery module assembly line of YIFI Laser can be applied to pouch cells of different structures and sizes. It can handle tabs on both sides and one side types of cells. The scope of application covers almost all mainstream soft pack batteries such as 355*157*113, 390*157*113, 580*330*109, etc. At the same time, the production line is compatible with modules of various specifications and sizes, ensuring that all modules required by customers for PACK battery packs can be integrated on the same production line to improve product consistency.

Third, the welding quality real-time inspection system and MES management system are integrated and applied, and the yield and consistency of the production line are more guaranteed.

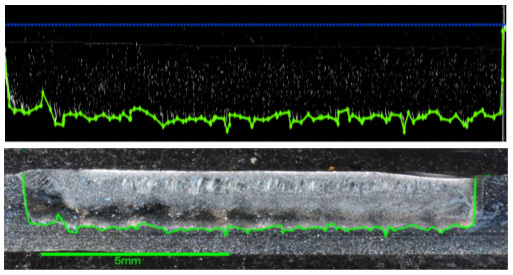

Based on the big data of welding process accumulated over 15 years, YIFI Laser uses a variety of automatic laser welding detection technologies for online detection and analysis. The equipment is equipped with the domestic leading LDD online detection system, and it is integrated with the MES management system to perform real-time detection and feedback on the quality of laser welding, and improve the production line yield and product consistency.

YIFI Laser welding quality real-time inspection system has the ability to monitor penetration depth that is not available in traditional welding monitoring systems. The system can provide penetration data of the entire weld, the penetration fluctuation can be controlled within 200um, and good products and defective products can be identified within this accuracy range. The welding station can monitor the surface after welding, find blast holes or weld defects, can effectively pre-detect the gap between welding materials and perform real-time feedback and adjustments to prevent incoming unqualified materials from flowing into the welding process. It reduces processing costs and guarantees high product yield and good consistency.

The intelligent assembly line of YIFI Laser soft package module makes production more efficient, with low cost, high productivity, higher safety, stability, reliability, long service life, and short production cycle. The breakthrough and innovation of PACK welding technology for soft pack battery modules further strengthened our company's position in the field of intelligent assembly lines for power battery modules.

At present, YIFI Laser has provided a number of battery companies with prismatic battery cell assembly line, full-tab cylindrical battery assembly line, prismatic battery cell module PACK line, soft pack module PACK line, and a cylindrical battery cell module PACK line. A number of other product lines have achieved full coverage of the manufacturing process from roll core/cell on-line to reel assembly/mold assembly off-line.

Global Service Hotline :

400-99-18650