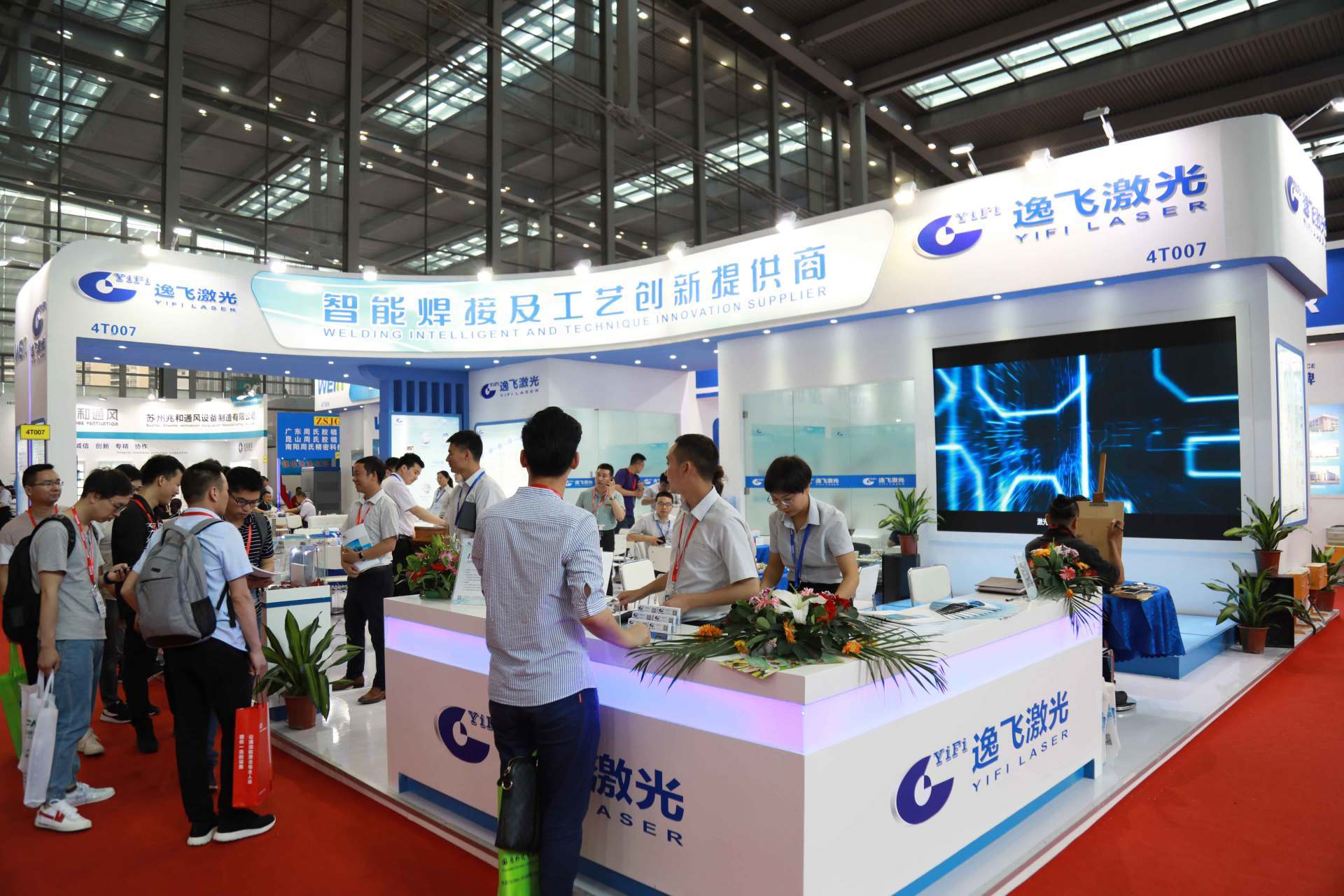

YIFI laser stunning appearance in CIBF has been focused by major domestic media

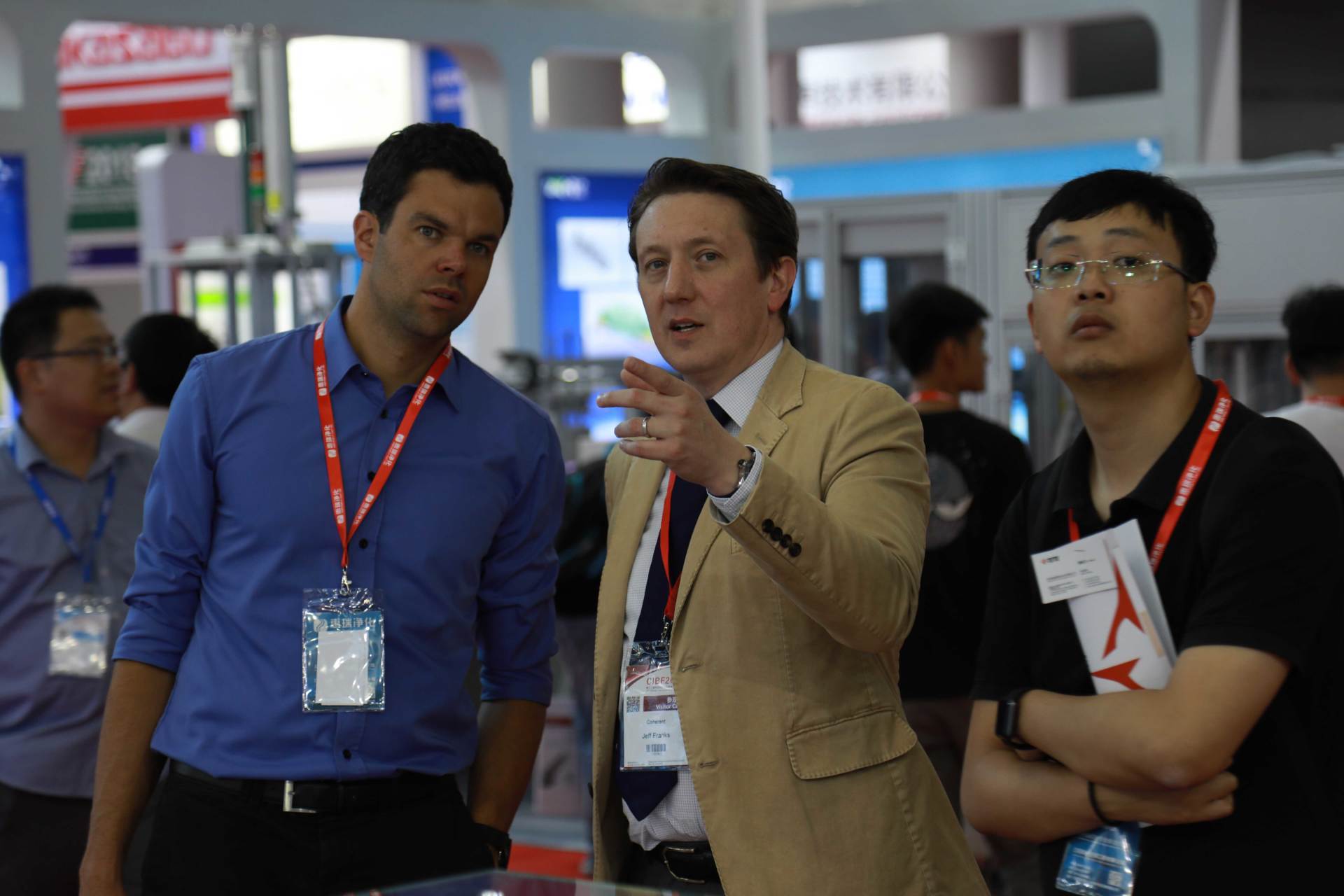

From May 22nd to 24th, the 13th CIBF China International Battery Technology Conference/Exhibition was held at the Shenzhen Convention and Exhibition Center. YIFI Laser carried its laser intelligent welding solutions and core products and fully demonstrated the innovative process of laser welding in the field of power battery manufacturing, attracting the attention of many domestic professional media.

According to the data provided by CIBF 2018 organizer China Chemical and Physical Power Industry Association, the exhibition is larger, with a total area of 110,000 square meters and 5,500 booths. The number of exhibitors at 1,250 has once again set a new record. According to incomplete statistics, the total number of visitors to CIBF2018 exceeded 60,000.

Thanks to the rapid growth of demand for new energy (electric) vehicles and energy storage markets, China's lithium battery, especially the power lithium battery industry, has begun to erupt in the development period, and the field of power battery equipment has also entered the stage of gold growth. According to industry analysis, during the 13th Five-Year Plan period, the investment in power batteries will reach 56 billion yuan, and the demand for laser equipment will exceed 5.6 billion yuan.

The key indicators that constrain the development of electric vehicles are the safety, cost and energy density of power batteries. Due to the complexity of the manufacturing process of the power battery and the high safety requirements, laser welding technology has become one of the key process technologies in the production process. The laser welding process of the power battery consists of battery soft joint welding, top cover welding, sealing nail welding and module PACK welding.

Power batteries are a particularly critical part of the overall production process, and it is not easy to solder loose raw materials into stable cells and PACK modules. Laser welding is a non-contact, high-precision, and highly efficient welding method in a variety of welding methods. It can economically and quickly weld and seal battery structural parts. Laser welding has also become the mainstream choice for power battery welding.

Since power battery manufacturing is a sunrise industry, many laser companies have begun to grab the power battery welding market, and everyone expects to get a piece of it. However, the process is difficult, the development time is long, the technical requirements are high, and it is necessary to constantly adapt to the iterative update of the new technology, so the entry threshold is higher. Accuracy, efficiency, and intelligence have become key points in testing the strength of laser welding equipment companies. With the continuous expansion of the production scale of power batteries, battery factories have put forward higher requirements for consistency and reliability in the manufacturing process.

Since almost none of the automakers in the market use the same module and production process, this puts more demands on the design of the automated production line. The module is not fixed, the incoming battery and the housing The connection between the bus and the BMS system may change, and the compatibility of the production line is especially important.

At present, industrial end customers are increasingly demanding the entire line of delivery, which is also more demanding for equipment manufacturers. It is necessary to coordinate the design of complex processes, digital, automated and intelligent seamless connection between equipment and equipment. To achieve "turnkey projects", a single company is often difficult to achieve, instead must rely on industrial collaboration to complete.

YIFI Laser has been committed to the development and application of intelligent laser welding systems for many years. In 2007, it officially entered the field of laser welding and related applications for new energy vehicle power batteries. YIFI Laser is a professional lithium battery cell, module and PACK solution provider in China. It is also a supplier with comprehensive technology reserves and wide customer distribution. With the concept of “flexibility” and “automation”, YIFI Laser effectively solves the problem of lack of compatibility and efficiency. Its creative model allows independent laser welding workstations to be combined with automatic lines to form a full line and can be used separately.

In fact, YIFI Laser has developed a set of logic suitable for its own development, further optimizes the company's industrial layout, provides customers with better service, realizes double the growth of sales, and integrates the advantageous resources of the industrial chain in the new energy automobile market. Lithium battery automation, laser process technology research and other aspects of strategic cooperation to achieve mutual benefit, to help the breakthrough of key technologies in the new energy industry, and promote the transformation and upgrading of the industry. “Each battery manufacturer has different production processes due to different manufacturing processes. Therefore, the problems encountered are different. Whether to provide stand-alone equipment or only laser components or provide a total solution, all need to be based on customer actual conditions. Demand is determined by the situation on the spot.” Wu Xuan, general manager of YIFI Laser, said that to choose the most suitable solution for the company. This is not only related to cost compression, efficiency improvement, but also overall consistency and final product. quality. Therefore, before providing the products, YIFI Laser will firstly communicate and understand the customer's needs, the requirements and even the production line process, and clearly define the requirements, and strive to provide customers with more suitable laser solutions.

Global Service Hotline :

400-99-18650